|

Home | Issues |

Articles |

Experimental Aviation Glossary |

Video Hints for Homebuilders |

Q&A |

A Personal View |

Polls

08/08 - John Steere’s Supercharged Thunderbird

Powered BD-4

Story By John Steere

Photos by Pat Panzera

We first reported on John Steere’s BD-4 in issue

66 of CONTACT! Magazine. A few years ago, we ran into John at AirVenture and

asked him to give us a follow-up report. Here’s what he sent us:

THE AIRPLANE

The plane is a BD-4, completed in May of 2000. The BD-4 was chosen because

it was easy to build, relatively inexpensive, carries four people, and is

relatively fast. Never satisfied with the status quo, significant modifications

were incorporated to accomplish specific objectives. The wings were lengthened

twenty-two inches per side, the flap length increased by the same amount, and

the flap deflection increased from 30 to 40 degrees, all to reduce the stall

speed. The wing was changed from the original fiberglass wing panels to aluminum

in an effort to reduce the fuel leakage problem frequently experienced with the

fiberglass panels. Rudder trim was added, and both stabilator and rudder trim

are driven by small, industrial, DC gear motors controlled by a small electrical

joystick located between the front seats. The doors were modified to hinge from

the top rather than the front, and were supported with gas springs. The

objective was to enable opening the doors in flight for better photography. It

also significantly improves cabin cooling while on the ground on hot days.

ENGINE

An automotive

engine was chosen because I could not rationalize the value of a conventional

aircraft engine, and I enjoy a technical challenge. This engine satisfied both

of these issues.

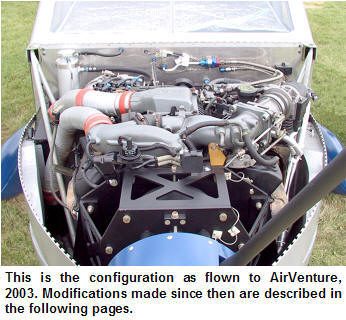

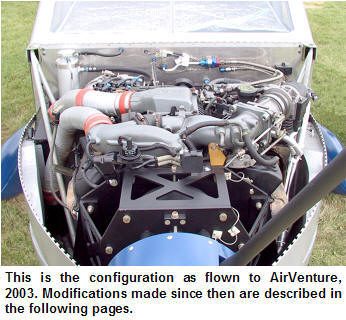

The engine is a 90-degree, 3.8-liter V-6 from a 1990

Thunderbird Super Coupe. It is supercharged by an Eaton blower and intercooled.

The compression ratio is 8.2: 1 and the fuel is supplied by six fuel injectors.

The engine is rated at 210 hp at 4000 rpm and delivers 315 lb-ft of torque at

just 2600 rpm.

Among other essentials such as a

Northwest Aero Products 1.7:1 ratio cog belted propeller speed reduction unit

(PSRU), this automobile engine conversion includes the standard automotive

sensors, multi-port fuel injection system, and computer ignition systems, less

the standard emissions junk. An emissions air pump (not standard in the car) was

added to serve as a vacuum source for the flight instruments.

|

|

|

The philosophy used to convert the

engine for aircraft use was - don’t change anything unless absolutely necessary.

Lacking automotive engineering credentials, the safest tactic was to keep

the conversion as simple as possible. There was no reasonable way to improve on the thousands

of engineering hours that Ford invested in the development of this engine.

However, some external adaptations were required to match the engine to the

airplane.

|

COOLING SYSTEM

A thorough study of available

data on water-cooled aircraft engines was completed and data from the most

successful installations was used for guidance. The data indicated the design

targets for the active frontal area of the radiator should be one square inch

per horsepower, and the radiator volume should be 2.52 cubic inches per

horsepower.

A radiator shop in Indianapolis was used to

fabricate the custom design based on the design targets. Assuming the engine

would produce the factory rated horsepower, the radiator was to be 23.5 inches

wide, 9 inches tall and 2.5 inches thick. There are small tanks on each end with

1.25” hose connections, a small drain valve in a lower corner, and a flange on

the upper surface to mount it to the airplane. The radiator is riveted directly

to the fuselage, perpendicular to the air stream. The radiator is connected to

the engine by 1.25” thin wall aluminum tubes running from the firewall to the

belly scoop under the fuselage. These are enclosed in a small tunnel for drag

reduction and appearance.

The belly-scoop, made from foam and fiberglass,

slips over the radiator from below and is fastened to the fuselage with four

bolts in the corners. Guidance from NACA publications dealing with inlet and

outlet configurations used in warbirds was used for the belly-scoop design.

When the shop completed the radiator, I found it to

be much thinner than I had requested. Instead of the specified 2.5 inches thick,

it was only 1.2 inches. Based on his experience with auto racing, the shop owner

believed it would be sufficient. So I mounted it and flight-testing has proven

that he was basically correct. However, there have been times on hot days,

during long climb outs, that the thicker radiator may have been beneficial.

EARLY DEVELOPMENT ISSUES

One of the early issues with the engine was an

intermittent misfire that occurred sporadically during full power climb-outs.

After eliminating every other possibility, I removed the fancy, high

performance, spiral core spark-plug wires that were advertised to be far

superior to the OEM equipment, and replaced them with OEM resistive wires. The

misfire problem was fixed. I did not say solved, because the actual underlying

cause is not understood. It may have been an impedance mismatch with the high

voltage coils. This is one of the areas where straying from the “don’t change

anything unless absolutely necessary” rule generated an unnecessary problem.

FUEL FLOW

For the first 100 hours or so, the plane was burning

about 13.5 gallons per hour in cruise, and the exhaust was very sooty. The

primary contributor is the OEM computer programming that adopts a

wide-open-throttle (W.O.T.) algorithm when certain operating parameters are met.

In the W.O.T. mode, the computer stops looking at the oxygen sensors to

determine how to adjust the fuel injection duty cycle and switches to an open

loop mode, using a look-up table that injects a predetermined amount of fuel

based on data from the mass airflow sensor (MAF). To protect the engine, this is

designed to be a rich mixture. Unfortunately, the computer defaults to this mode

for any power setting greater than that required for minimum cruise.

|

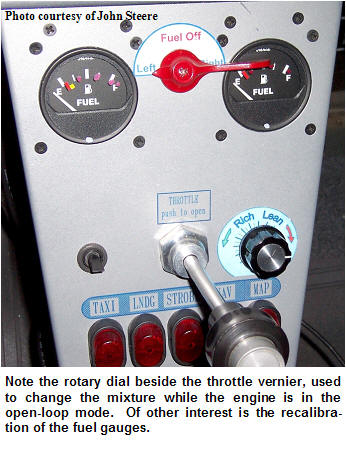

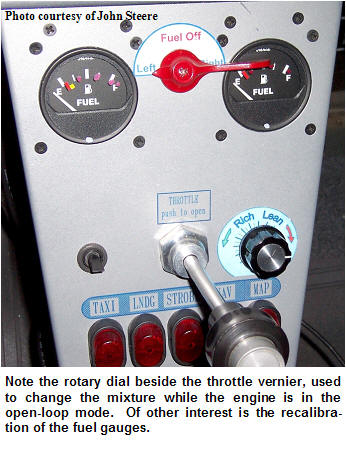

To overcome this problem, a passive voltage divider

circuit was designed and placed between the mass airflow sensor and the

computer. (See diagram.) This circuit supplies an adjustable percentage of

the signal from the MAF to the computer. This causes the computer to think the

engine is taking in less air than it actually is, so the computer tells the

injectors to deliver less fuel. The manually adjustable potentiometer is

positioned next to the throttle, allowing the mixture to be adjusted in flight.

The potentiometer is the only component in the circuit that has any significant

potential for failure. Its likely failure mode is to electrically open rather

than short out, so it’s positioned in the circuit where a failure

will cause the mixture to go rich if it opens, - a safe condition.

|

|

| |

|

On this water-cooled engine the EGT does not peak

then noticeably drop off as the mixture is leaned. The leaning procedure that

seems to work best is to slowly lean until the engine starts to run rough, then

enrich the mixture until it runs smoothly. This yields a 65-70% cruise fuel burn

rate of 10.5 to 11 gallons per hour of premium auto fuel. It has not been

necessary to enrich the mixture at low power settings, for starting, or ground

operations. During low power settings, the computer returns to the closed loop

mode and operates smoothly.

INDUCTION CHANGE

The original induction

system was a simplified version of what was supplied in the car. Due to size

constraints, the original ducting and resonator (shown right) were eliminated

and replaced with a flexible tube that carried induction air from a T-Bird air

filter directly to the MAF sensor. The air filter was positioned in a plenum

immediately behind a NACA flush inlet on the left side of the cowling.

This system worked OK, but took up a lot of space,

and I was concerned that the air filter might soften and collapse into its

plenum if the plane was flown through a heavy rainstorm. The air filter location

was also the only practical place to mount a larger oil cooler that was needed

to extend the time between oil changes.

|

|

| |

|

|

In late 2003, the decision was made to reconfigure

the induction and oil cooler systems to get them off the worry list. At Auto

Zone, a simple well-constructed cone filter was found with an exit flange that

fit perfectly into the inlet of the mass airflow sensor. (See photo to the

right) The opposite end of the cone filter is supported by an |

|

aluminum bracket attached to

the engine mount by an Adel clamp. This all fits neatly under the cowling and

ends the concern about a wet filter collapsing and choking the induction system.

I may be paying an imperceptivity small power penalty since the induction air

drawn from under the cowling is warmer than air sourced through the original

NACA flush inlet.

The original oil cooler was a small, single loop,

unit set in the NACA inlet plenum on the right side of the plane, immediately in

front of the intercooler. With the NACA flush vent on the left side now

available, the eleven-inch square plenum was filled with an automotive oil

cooler. The effect on oil temperature was very gratifying. With both

measurements taken on 70° F days, the oil temperature dropped from 232° to

210°. With the new oil cooler now taking on a larger share of the overall

cooling load, the water |

|

|

temp. dropped from 227° to 220° F. Very satisfying

results for an amateur. |

|

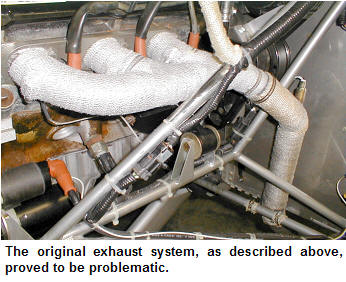

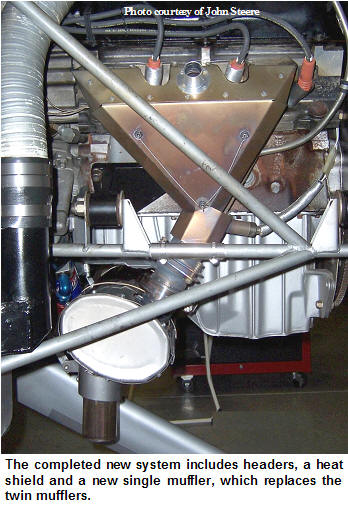

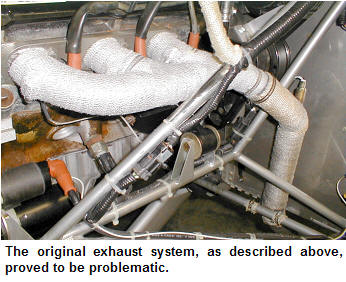

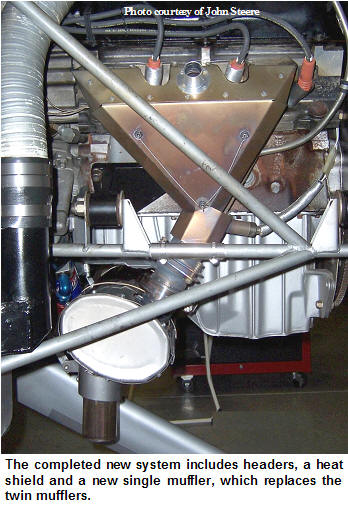

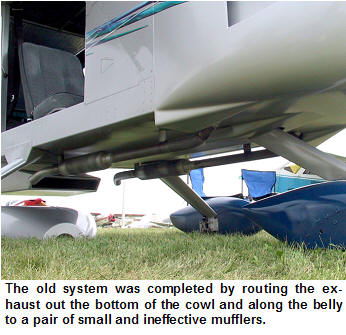

EXHAUST SYSTEM

The exhaust system has been the most troublesome aspect of the engine

conversion. The original headers were fabricated from mild steel tubing as a

cost savings choice. Bad decision! Because the original header design brought

them within ¾” of the sparkplugs, they had to be insulated with an exhaust wrap

to protect the sparkplug |

|

|

boots.

The insulation was very effective, but did not last long. Within ten hours it

lost its flexibility, and if you inadvertently touched it while working on

something nearby, it would fracture and break off. The more serious matter was

the higher manifold temperature caused by the insulation. With any cooling air

to the header effectively blocked by the insulation, the mild steel overheated

and finger sized holes developed in both headers within twenty hours.

New exhaust headers in the same general

configuration (mistake #2) were fabricated from 321 stainless. I inadvertently

ordered the bends with a larger radius (mistake #3) than used with the mild

steel header, resulting in the tube passing within ½” of the plugs.

|

|

|

The

stainless tubing held up to the heat. But even with the insulating wrap, a

sparkplug boot would occasionally break down, allowing an arc to occur between

the sparkplug and the header. This happened one time while my wife was on board,

leading to an emotional reaction to the sudden engine roughness, and a

significantly reduced confidence in the airplane. These events were not life

threatening since the airplane could still climb very well on five cylinders.

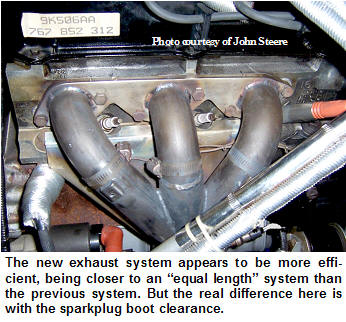

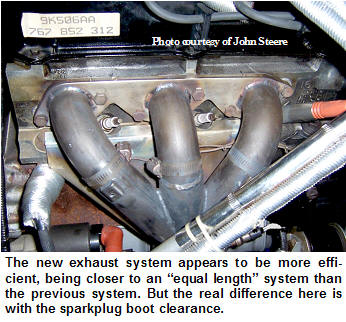

After several “five-cylinder” events, I decided to

redesign the entire exhaust system. The new design had to provide as much

clearance from the sparkplugs as possible, eliminate the need for insulation

wrap, and make accommodation for the under-engine muffler I wanted to add.

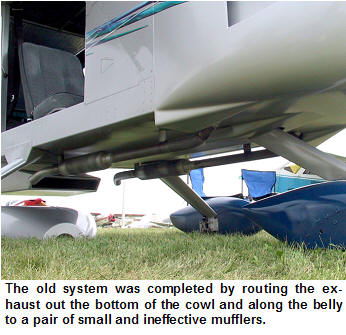

The original header design brought the header

straight back towards the firewall (see first photo |

|

in the series at the left) before dropping down to

exit just ahead of the firewall. The new design drops immediately from each

exhaust port, with the three tubes joining approximately 8 inches below the

ports. This |

|

significantly improves the clearance from the sparkplugs and

provides a more direct route towards the bottom of the cowling. Below the “Y”

connection, the tubing diameter changes from 1-3/4” to 2”, and the oxygen sensor

mounts just below the “Y”. The 2” tube continues down to a ball joint, then

terminates with a V-Band clamp that enables removal of the exhaust pipes or

muffler without removing the headers.

The exhaust manifolds are enclosed in a thin

(0.025”) stainless steel heat shield to prevent excessive radiant heating of

adjacent components. (See photo at right). The heat shields include 1” air duct

couplings where outside air is introduced to provide in-flight manifold cooling.

The sparkplug boots are also enclosed in protective sleeves because they are

still too close to those glowing header pipes. This header arrangement has

worked well since its installation about 40 hours ago, eliminating those

annoying “five cylinder” events.

This system was flown for about 38 hours with

straight pipes plus a crossover tube attached to the V-Band clamps. This system

performed very well, but the noise made communication in the cockpit, even with

an intercom and good, noise-canceling, headsets very difficult. The neighbors (I

live in a fly-in community) also said that the noise made the trees rattle

during take off.

|

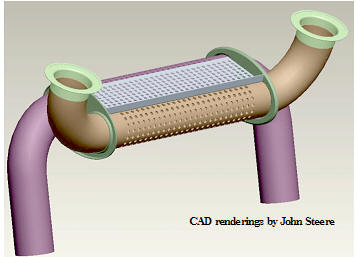

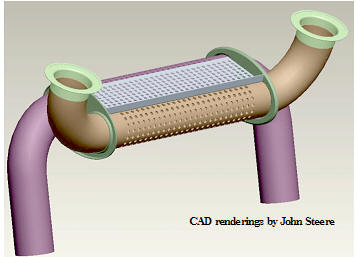

MUFFLER

For both of the previously stated reasons, a muffler was in order. Due to

the tight cowling and cramped quarters under the engine, a suitable

off-the-shelf muffler that would physically fit could not be found. So, I

designed a muffler that would fit the available space, and hopefully provide enough internal baffling to

reduce |

|

the noise without causing too much back pressure. Since I am not a muffler engineer, some elementary

research was required. An Internet search disclosed that there are five basic

principles available for use in passive mufflers – reflection, absorption,

restriction, expansion, resonance, and combinations of these. Space constraints

limited options for this application primarily to the restriction realm.

The muffler consists of two “U” shaped tubes, two

baffle plates, two end caps, and an outer skin. The tubes are 16 gauge, 321

stainless, and the baffles, ends, and wrap are 0.025” thick 304 stainless, all

welded together with 308 stainless filler rod. The end caps were shaped using

wooden form blocks for the perimeter, and simple turned steel

mandrels to form the holes for the tubing. The tubes are preformed 90° bends

welded end-to-end in the center of the muffler.

|

|

|

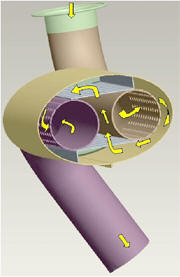

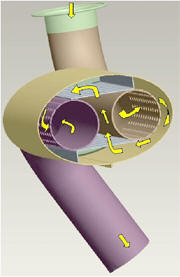

The exhaust gasses enter from both ends of the

flanged exhaust pipe, exit the pipe through a series of ¼” holes along the

forward surface, then travel downward (because they are blocked by a bent-up tab

on the upper baffle.) They then pass through the lower baffle, between the two

pipes, through the upper baffle, through perforations into the tail pipe, and

out the ends of the tail pipes to the atmosphere. Each set of perforations has

about twice

|

|

|

the open cross-sectional area of the tubes.

The entire muffler is enclosed in a stainless steel

heat shield (not shown), including the exhaust pipes, until they exit the lower

cowling. Cooling air is introduced between the heat shield and muffler by way of

a 2” air duct. The cooling air is exhausted between the tail pipes and

their heat shields. This cooling air is not used for cabin heat as there s a

welded joint running the length of the muffler skin, and there is

another, safe source for cabin heat.

The effect of the muffler was immediately apparent

when the engine was started after installation. The noise in the cockpit was

|

|

significantly reduced to the point that intercom communication was possible

without turning on the noise canceling in the earphones. That’s not to say that

I wouldn’t like it quieter, but the noise has dropped from oppressive to

operationally reasonable in the cockpit.

|

|

The effect on power has yet to be fully analyzed,

but does not seem to be significant. Supercharger boost pressure during takeoff

has increased from 9 PSI to 11-PSI, and at cruise RPM (2400,) the pressure

increased from 2-PSI to 3-PSI. With all else remaining the same, boost pressure

is related to back pressure in the exhaust system. The 11-PSI full throttle

boost is still less than the 12 to 14-PSI normally seen in the 1990 T-Bird Super

coupe from which this engine was removed.

CABIN HEAT

I am not comfortable using the exhaust system as a

cabin heat source unless the heat muff could be mounted over an area free of

welded joints. The new, compact, exhaust system doesn’t offer that choice. Water

cooled engines also provide the option of using a small automotive heater core

as a safe heat source, but require additional plumbing, add some weight, and

take up space for the heater core and a circulation fan. With the engine

compartment and both sides of the firewall rather crowded, the heater core was

not a good option. Fortunately, |

|

|

there is another source for

safe, warm air from a super charged engine – the intercooler. Cooling air for

the intercooler enters through a flush NACA inlet on the right side of the

airplane and passes through the intercooler, into an exhaust duct that directs

the warmed air out the bottom of the cowling, just ahead of the firewall. A

two-inch air duct flange through the firewall, coupled into the

intercooler exhaust duct, captures part of the warmed air and delivers it to the

cockpit through a butterfly valve. The intercooler only provides warm air when

the supercharger is actually pressurizing the induction air, so there is no heat

while on the ground. Since this system is pressurized by outside air through the

NACA inlet on the side of the cowling, there is no risk of carbon monoxide

poisoning. |

FUEL GAUGE CALIBRATION

I learned a very important lesson a couple years

ago, while on a return flight from Western Michigan to my home base, Twelve Oaks

Airport, Martinsville, Indiana (II87), about 16 nautical miles South of

Indianapolis. Shortly after passing Indianapolis Metropolitan airport, the

engine quit. A quick scan of the fuel gauges indicated about six gallons

remaining in the left tank, (the tank from which the engine was drawing fuel),

and about ten gallons in the right tank. I immediately switched tanks, turned on

the second fuel pump, and said a quick but urgent prayer. I then remembered that

Metro airport had just passed under my right wing, made a quick right turn, and

found myself perfectly set up on downwind for runway one-five.

I continued looking for the source of the problem on

down-wind, believing it to be fuel related due to the way the engine died - a

smooth RPM reduction over a period of about three seconds. But I had very

carefully calibrated the fuel gauges while building the airplane, and had marked

the gauges at several points with the actual fuel level, and the gauge still

showed six gallons. As I turned onto a short final, with the prop windmilling,

the engine restarted on its own. I landed and taxied to the ramp, with

everything performing normally. A visual check of the left wing tank found it

completely dry.

After thinking about this for a few minutes, it

dawned on me that the procedure used for calibrating the fuel gauges was faulty.

The gauges were calibrated while the plane was still in the basement, with the

plane on battery power - about twelve volts. In flight, with the alternator

charging, the electrical bus is carrying about fourteen volts. That two-volt

difference caused the gauge to read six gallons higher on the low end of the

scale. Needless to say, the fuel gauges were recalibrated with the engine

running.

NOSE WHEEL

The

BD-4 uses a castering nose wheel with a spring-loaded friction pad around the

spindle to prevent nose wheel shimmy. Early in the flight-testing, the spring

pressure was reduced because the brakes were wearing rapidly as I fought the

nose wheel during mile long ground excursions. Unfortunately, the reduced

friction allowed the nose wheel to shimmy aggressively. After fighting the

friction adjustment battle and other unsuccessful mechanisms for three years,

and destroying two nose wheel pants, the decision was made to add a hydraulic

damper. Not wanting to pay the ridiculous cost of an aircraft damper, a search

for alternatives was in order. An Internet search led to a self-centering damper

that in normal life is used to control hydrostatic transmissions, typically

linked to a control lever or pedal to provide a controlled rate of actuation.

This little unit cost less than $50, and has eliminated the shimmy problem. Now, a new wheel pant is in order.

For additional information about this plane, go to:

www.bd-4.org/builderlist_sheet.php?session=&id=42&user=John%20Steere

CONCLUSION

I stated in the first report on this plane, “I could

not rationalize the cost of a new or used 180-200 hp Lycoming engine (that the

airplane was originally designed to use) against my perception of the value of

the engine.”

To put things in perspective, I saw an advertisement

in a recent aviation periodical for a 180-hp. fuel injected aircraft engine with

FADC controls for $29,900. The Thunderbird installation, including the PSRU,

alternator, air pump, supercharger, fuel injection, computer control system, and

all the sensors and other incidentals needed to complete the system, cost

approximately $7,000. I think that is a pretty good value for a new engine with

21st century controls, rated at 210 hp.

All of that is still true, and based on the 185

hours of experience with this engine, I would choose an automotive engine again.

Hmm…. that Corvette LS1 engine looks interesting!

Comment on this article:

|